DEFINING BRILLIANCE BLOG

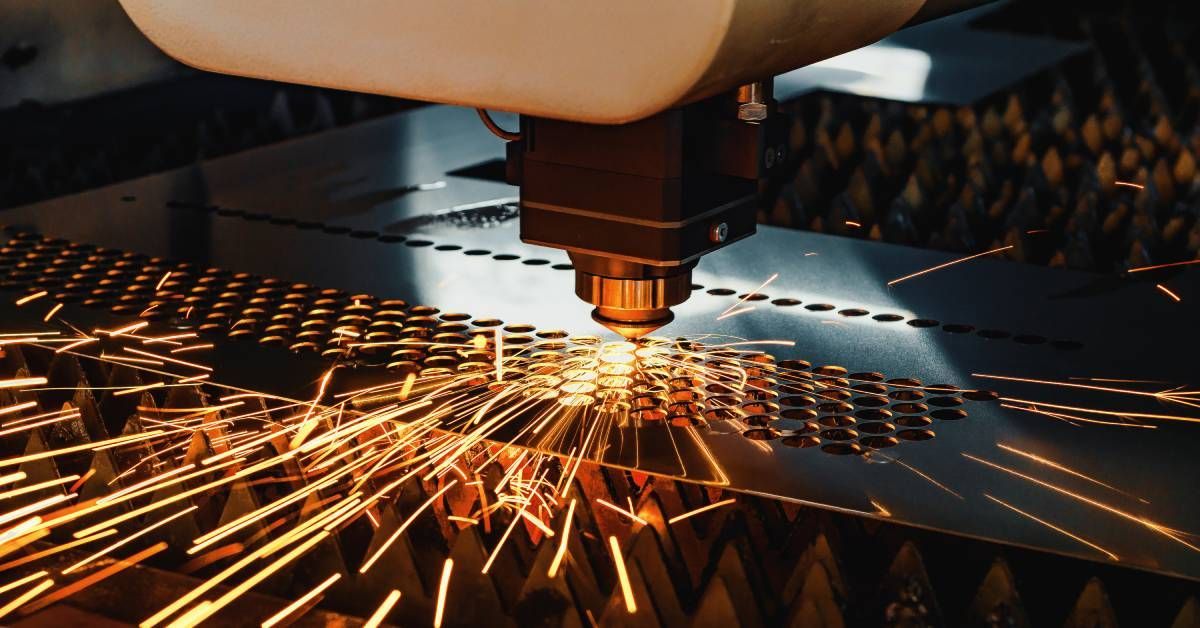

A Blog For Stainless Steel Manufacturers

Bookmark this page and check back often to find out what's new here at Custom Mfg. & Polishing!

We keep busy with innovating products and customized solutions for our customers, and we hope to inspire you by showcasing our work within this blog.

Our motto has always been, You Dream It, We Build It!

Newest Posts

CUSTOM MANUFACTURING & POLISHING, INC.