How Automation Has Impacted Steel Fabrication

Automation has transformed industries across the board, and steel fabrication is no exception. From the integration of robotics to data-driven systems, automation has had lasting effects on steel fabrication by streamlining workflows and producing precision-engineered results. These technological advancements play a major role in the steel manufacturing industry, by allowing businesses to deliver high-quality, tailored solutions with unprecedented efficiency. Keep reading to learn more details on how automation has impacted steel fabrication in recent years.

Efficiency and Precision

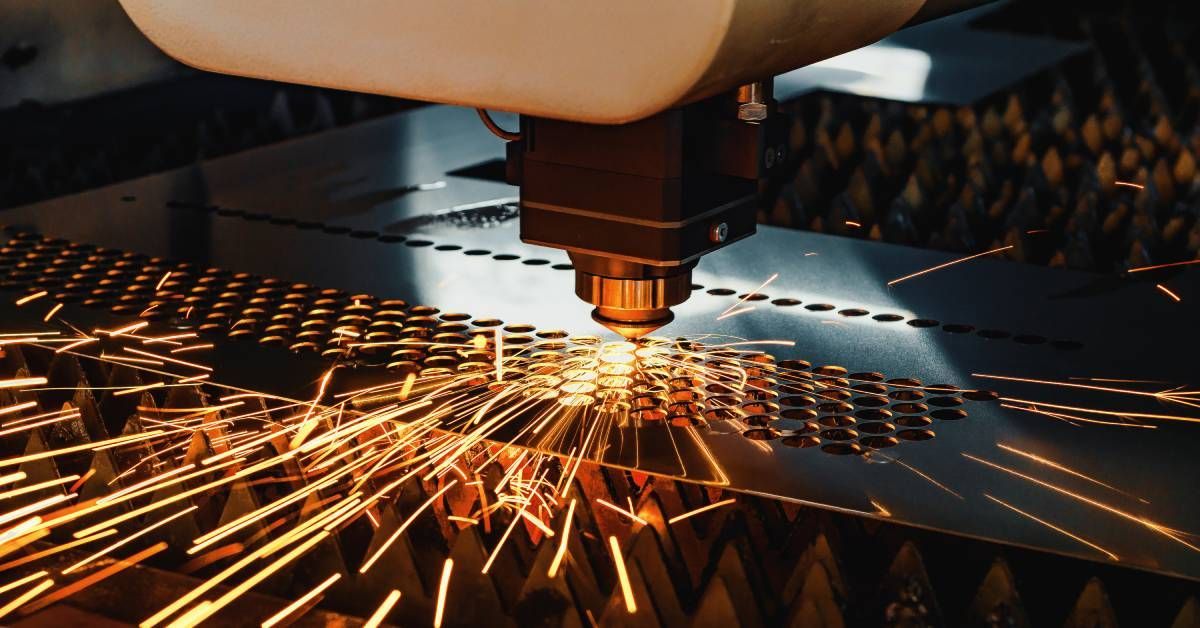

Automated systems have significantly improved the efficiency of steel fabrication processes. Tools such as robotic welding and CNC cutting machines complete tasks that once required hours of manual labor quickly and with remarkable accuracy. This efficiency reduces production costs and keeps projects on schedule without compromising on quality.

Precision is another key benefit of automation. Advanced technologies such as laser cutting and automated polishing systems deliver intricate results that are almost impossible to achieve manually. This level of exactness is vital in maintaining the high standards of custom stainless steel manufacturing, where clients expect bespoke designs with flawless finishes.

A Safer, More Cost-Effective Approach

Workplace safety has also seen a notable boost through automation. By handling high-risk tasks such as welding, cutting, and heavy lifting, automated systems reduce workers' exposure to potentially hazardous environments. This reshaping of the workplace protects employees and aligns with the higher safety standards across the manufacturing industry.

Although the initial investment in automation might seem daunting to manufacturers, it offers clear long-term savings. Automated systems minimize material waste while keeping operational costs low through increased consistency and reduced error rates. At CMPI, these cost benefits allow us to offer competitive pricing on custom fabrication and polishing without cutting corners on quality.

Flexibility for Evolving Industry Needs

Automation allows manufacturers to adapt swiftly to shifting market demands. Whether fulfilling niche orders or adjusting production to meet specific client needs, automated tools add flexibility and scalability to operations. This capability is particularly important for custom or specialized orders, where unique client specifications require innovative approaches.

Automation Issues and Solutions

Despite its advantages, automation in steel fabrication comes with challenges, such as high upfront costs and skill gaps among workers. However, ongoing advancements in AI and IoT promise to address these hurdles to pave the way for a more seamless integration of automation across the sector. Sustainable practices, such as reduced energy use and material waste, also strengthen the push for automation because of its role in creating a more eco-friendly industry.

Automation has impacted steel fabrication by making the industry more efficient and capable of precise results. Companies like CMPI exemplify how automation and expertise can work together to deliver high-quality, customized solutions. Explore our services today to learn how our innovative processes can support your next project.