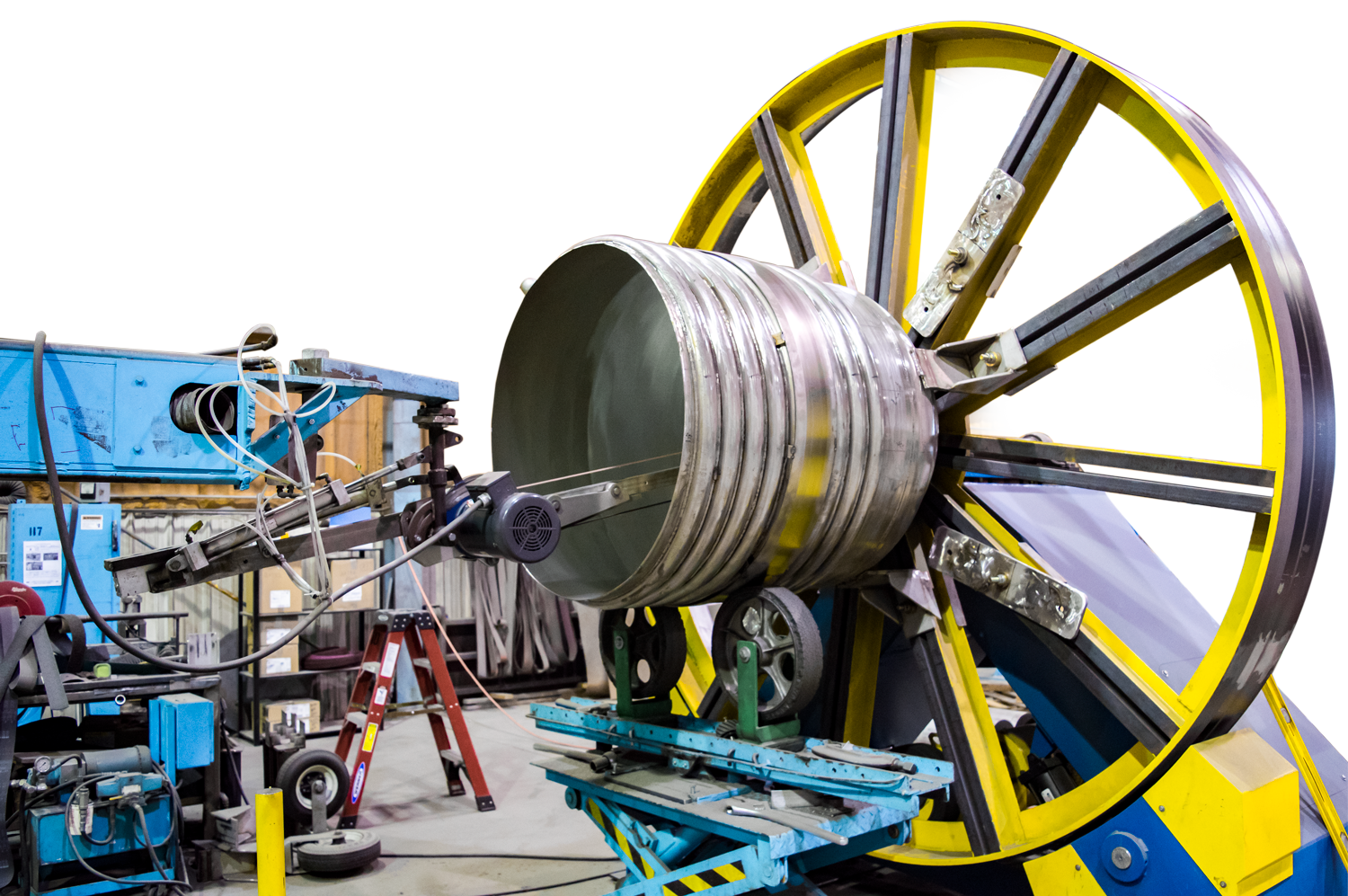

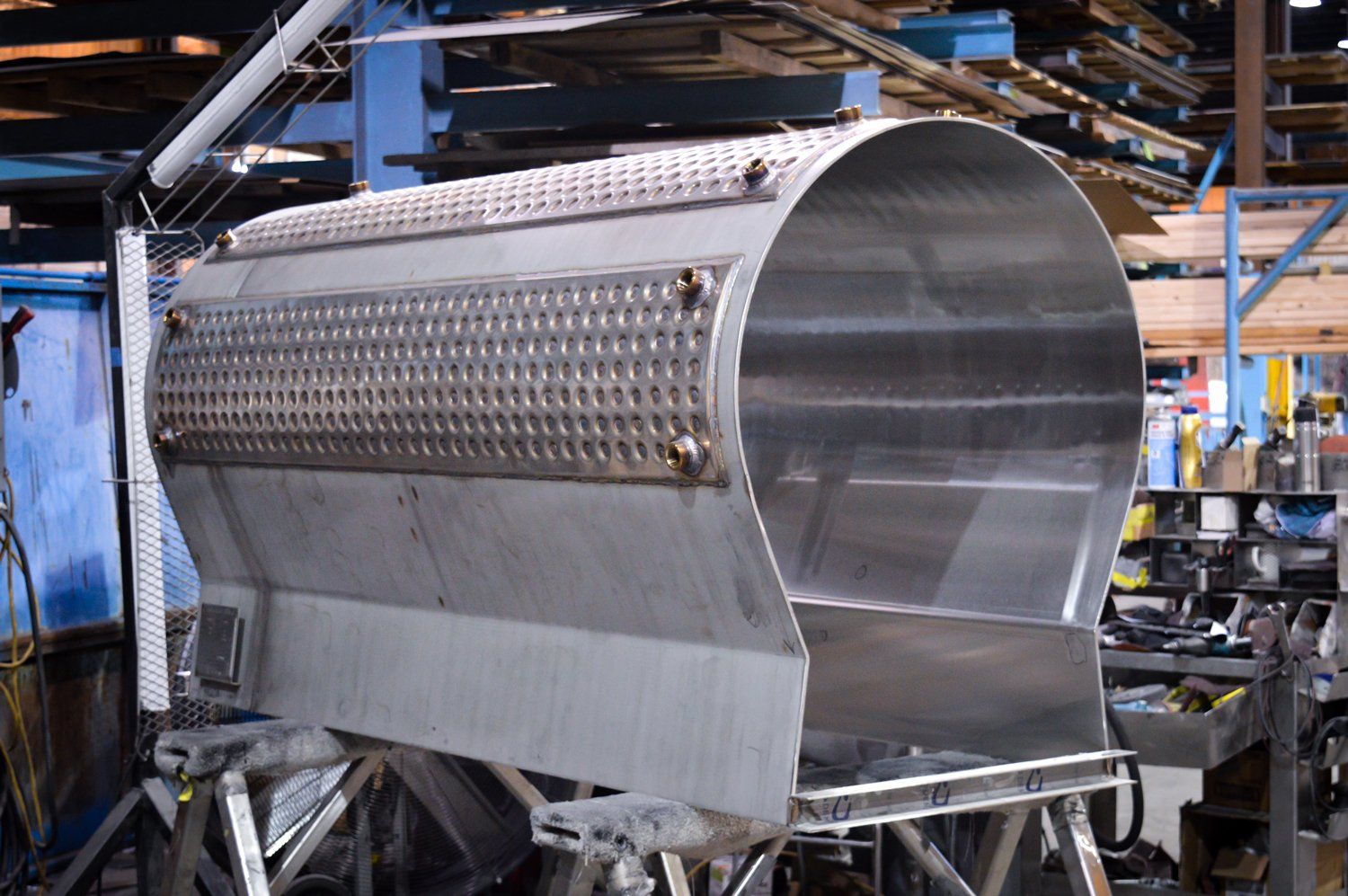

Spin Polishing Capabilities

I.D. / O.D. · High Capacity

To learn more about our heavy-duty tank and vessel polishing services, please contact us today! Our team of experts will be happy to assist you with any inquiries or projects you may have.

TURN-KEY Service - The CMPI Advantage!

Save time

Customization

Friendly support

Discount material

Contact Us For Stainless Polishing!

At CMPI, we want to be an extension of your plant. Each client has unique jobs, and over the years we've innovated creative solutions for problem-projects, big and small.

If you don't see the services that you require listed here but you think we could help, contact us! Your custom job might be a perfect fit for our versatile shop.