The Future of Stainless Steel Sheet Production

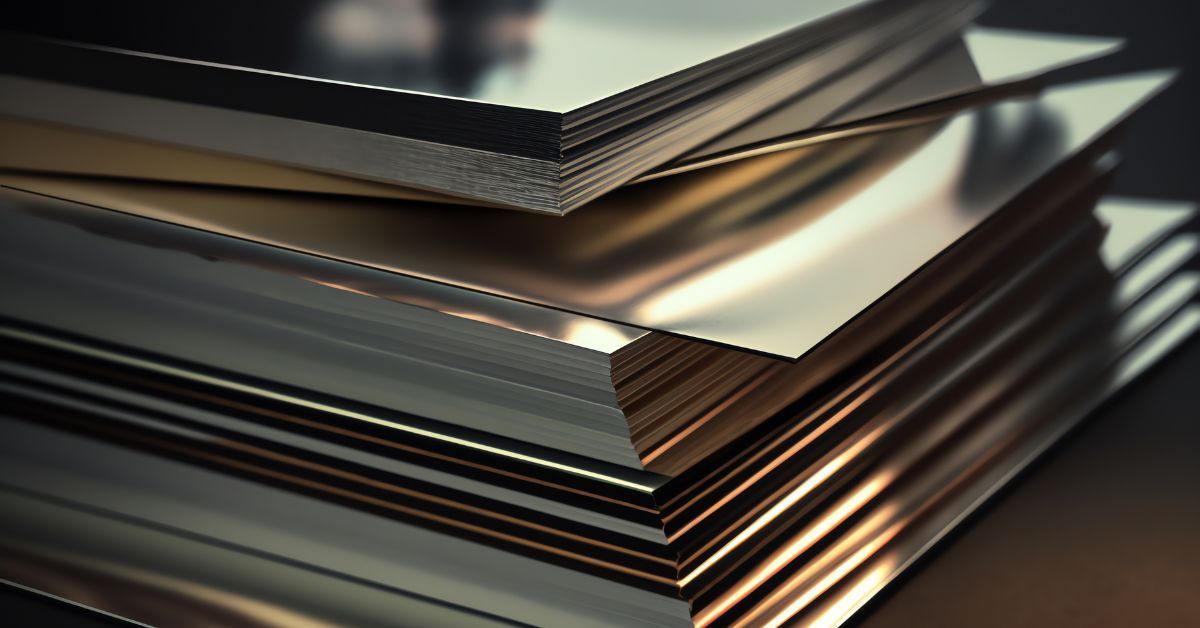

Since its discovery in the early twentieth century, stainless steel has become indispensable in various industries thanks to its corrosion resistance, durability, and aesthetic appeal. Initially used in cutlery, its applications have expanded into construction, automotive, and aerospace sectors, among others. Stainless steel sheets stand out for their versatility and have played a pivotal role in industrial advancement, serving as a solid backbone for modern architecture and manufacturing.

However, with the growing concerns over climate change and depletion of natural resources, the production of stainless steel sheets has come under scrutiny for its environmental impact. Continue reading for an in-depth analysis of the future of stainless steel sheet production and the importance of sustainability and innovation.

Common Uses of Stainless Steel Sheets

Stainless steel sheets are durable and have a sleek finish, making them a favorite in not just heavy-duty industrial settings but also in consumer goods like appliances and electronics. In the automotive industry, stainless steel sheets contribute to both the structural integrity and design appeal of vehicles. In the construction industry, stainless steel sheets are present in facades, roofing, and interior applications. The food processing and medical industries also rely heavily on these materials for their hygienic properties.

The Importance of Polishing

The polishing of stainless steel sheets is more than just a finishing touch; it’s a crucial process that enhances the material’s functionality and longevity. Polishing not only improves aesthetic properties but also increases corrosion resistance—a key attribute of stainless steel. This added layer of protection is essential for applications where durability and hygiene are paramount, making polished stainless steel the material of choice for a multitude of purposes.

Advancements in Stainless Steel Sheet Production

The traditional method of producing stainless steel sheets involves melting scrap metal and adding alloys to create the desired properties. This process is energy-intensive and emits significant amounts of greenhouse gases, contributing to the global carbon footprint. Moreover, the use of non-renewable resources, such as coal and iron ore, has raised concerns about sustainability in the long run.

To address these challenges, there is a pressing need for innovation in stainless steel sheet production. Through various technological advancements and process improvements, the industry must shift toward more sustainable practices that reduce emissions and utilize renewable resources.

Current Production Challenges

While stainless steel sheet production has become more efficient over the years, it still faces significant challenges. Environmental concerns top the list, with the manufacturing process being energy-intensive and contributing to CO2 emissions. Additionally, the cost of raw materials, such as chromium and nickel—which are crucial in making stainless steel—fluctuates significantly, impacting the overall cost of production. Manufacturers are also under constant pressure to enhance efficiency and reduce wastage during production.

Technological Revolutions Shaping the Future

The future of stainless steel sheet production lies in embracing technological innovations. Advanced manufacturing processes, including additive manufacturing and continuous casting, have started reshaping production dynamics. These methods not only improve efficiency but also reduce material waste. Additionally, automation in production plants is gaining momentum, facilitating consistent quality while minimizing human error and operational costs.

One of the key advancements in stainless steel sheet production is the use of electric arc furnaces (EAFs). Unlike traditional methods, EAFs use electricity to melt scrap metal, reducing carbon emissions and energy consumption significantly. This method has gained popularity in recent years due to its lower environmental impact and cost-effectiveness.

Another major innovation is the development of continuous casting technology, which allows for a more efficient and streamlined production process. This method involves pouring molten steel into continuous molds, resulting in consistent and higher-quality stainless steel sheets. Continuous casting also eliminates the need for reheating, further reducing energy consumption.

Navigating Innovation and Sustainability

Innovation and sustainability go hand in hand to ensure the continued success of stainless steel sheet production. As technology advances, manufacturers need to stay ahead of the curve by investing in research and development to improve processes and create more sustainable products. Collaboration among stakeholders, including raw material suppliers, manufacturers, and end-users, will also be crucial in driving progress. The stainless steel industry must prioritize sustainability and work toward reducing its environmental impact while meeting the demands of a growing global market.

The Role of Metal Fabricators

Metal fabricators play a critical role in the stainless steel sheet industry, acting as the bridge between raw materials and finished products. The adoption of cutting-edge technologies presents both opportunities and challenges for these craftspeople. On one hand, it offers them the tools to produce more with less, carving a path to profitability and environmental stewardship. On the other, it demands a shift in skills and mindset, and possibly even significant capital investment in new machinery and training. Yet, by driving change within their operations, fabricators can position themselves at the forefront of the industry’s evolution.

Predictions for the Future

Looking ahead, several predictions for the future of stainless steel sheet production emerge. Market trends indicate a growing demand for high-quality, environmentally friendly stainless steel sheets, driven by industries striving for sustainability and superior materials. This is likely to spur innovation in production techniques that are less reliant on finite resources and easier on the environment. Globally, the push for sustainable practices will only intensify, with regulations and consumer demand guiding the way. In response, the stainless steel industry will increasingly focus on circular economy principles, emphasizing the reuse and recycling of materials to minimize environmental impact.

The Need for Continuous Modernization and Collaboration

The path forward for stainless steel sheet production is clear—innovation and collaboration are essential. As the industry tackles current challenges and prepares for future demands, stakeholders at all levels must engage in continuous improvement and adopt new technologies. Metal fabricators, in particular, have a pivotal part to play in shaping the future, not just in mastering new techniques but in advocating for sustainable practices and leading by example. Together, the entire industry can forge a future where stainless steel continues to be a material of choice, known not just for its durability and versatility but also for its sustainability.

At CMPI, we specialize in stainless steel sheet plate and sheet polishing services. The ubiquity of stainless steel means more and more manufacturers are relying on us to provide stainless steel plates cut to size for a variety of specialized applications. With different thicknesses and finish styles to choose from, it’s easy to customize your project to your exact specifications. Get in touch with our team to let us know what style you need, and we can work with you to ensure your stainless material meets all your requirements.