Maintenance Best Practices for Plate Heat Exchangers

Plate heat exchangers (PHEs) are important in various industrial processes, including heating and cooling. To ensure these devices operate efficiently, you need to take care of them. Whether you are in the industry or curious about these common tools, learn these maintenance best practices for plate heat exchangers.

What Are Plate Heat Exchangers?

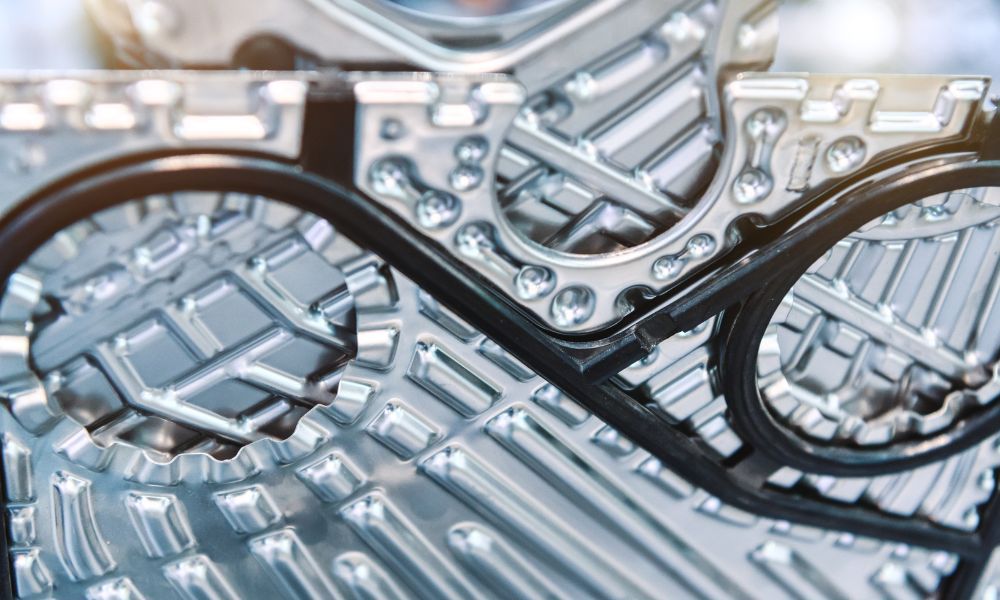

Plate heat exchangers transfer heat between two fluids of differing temperatures. Builders use them in HVAC and industrial systems and for power generation and refrigeration. Most heat exchangers include multiple stacked plates, creating parallel flow channels for different tempered fluids.

Maintenance and Care Tips

Regular Cleaning

One of the most critical maintenance tasks for PHEs is regular cleaning. Over time, fouling and scaling can build up on the dimple plate jacket and reduce heat transfer efficiency. The frequency of cleaning will depend on the fluids and the operating conditions, but it’s a good idea to clean the PHE annually or semi-annually.

Use Compatible Cleaning Agents

When cleaning your plate heat exchanger, use cleaning supplies and chemicals compatible with the construction materials. Most PHEs are made of stainless steel or titanium plates. Using the wrong cleaning agents, like chloride, can lead to corrosion and damage to the plates.

Inspect Gaskets

PHEs use gaskets to seal the plates and prevent cross-contamination between the fluids. Regularly inspect these gaskets for signs of wear and tear, and replace them when necessary to maintain a proper seal and prevent fluid mixing.

Clean-In-Place

Most of the time, you can clean your PHE with a clean-in-place method. This will flush out all debris that your device collects over time. Here are the steps to this process:

- Drain both sides of the PHE and dispose of the fluids.

- Flush water through both sides, opposite of the direction in which the fluid typically flows. Debris should come out at this point, so run water through until it is completely clear.

- Use a cleaning agent to clear out the PHE completely. You will need a circular pump and solution tank for this process.

If you can’t complete this process, you must clean your PHE manually. Open the plates and clean them with the cleansing agent without taking the plates out of the frame. You can also use a high-pressure washer for a more thorough job, but protect the gaskets from the intense stream if you choose this route.

Regularly Schedule Maintenance

Now that you have learned maintenance best practices for plate heat exchangers, you can create a schedule that outlines cleaning, gasket replacement, and inspections. Adhering to a strict and thorough schedule will help you stay on top of PHE maintenance so you can keep the device working effectively for a long time!