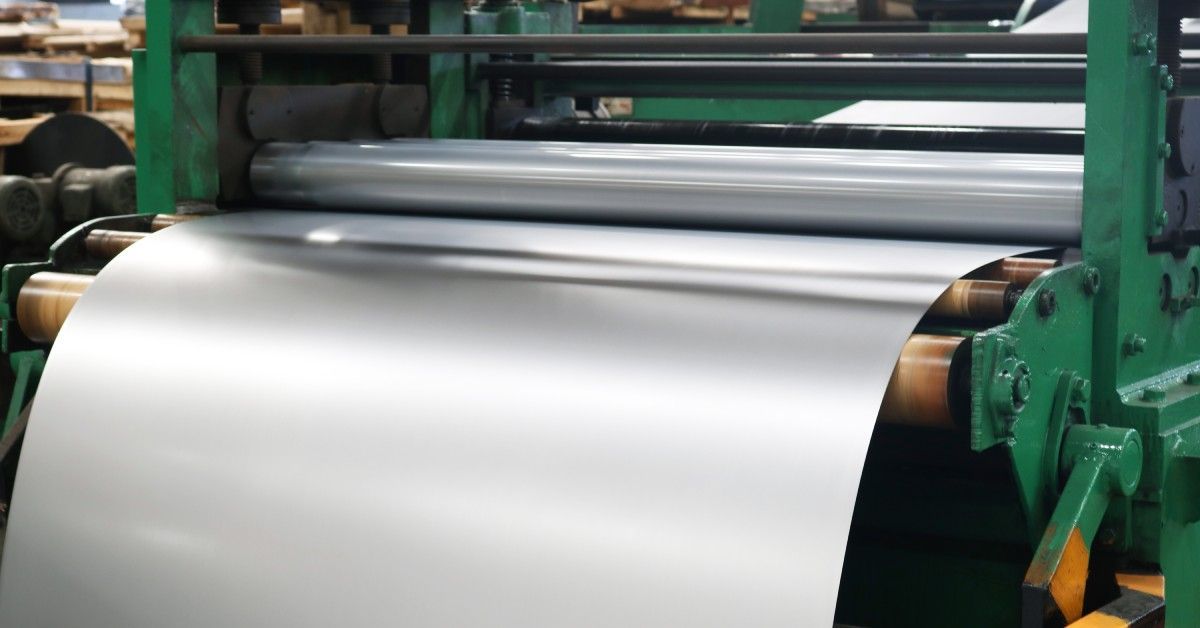

Different Types of Stainless Steel Polishing Techniques

Stainless steel is a staple in many industries—from automotive to kitchenware—reflecting its versatility and durability. However, the key to unlocking its full potential lies in the polishing process. Polished stainless steel not only looks aesthetically pleasing but also enhances the material’s corrosion resistance and cleanliness. Understanding the different types of stainless steel polishing techniques can help you choose the right method for your needs.

Mechanical Polishing

Mechanical polishing involves using abrasive tools or materials to smooth and polish the surface of the stainless steel. This technique removes imperfections and creates a uniform finish. The process may include grinding, buffing, and brushing, depending on the desired level of polish. One of the main benefits of mechanical polishing is the control it offers over the final appearance of the material—it’s particularly effective for achieving high gloss finishes. Mechanical polishing is ideal for applications where visual appeal is paramount, such as in architectural elements and consumer products.

Electropolishing

Electropolishing is a more advanced technique that uses an electrolytic solution to remove a thin layer of material from the surface of stainless steel. This process, often referred to as electrochemical polishing, results in a smoother, more reflective surface compared to mechanical methods. Electropolishing also enhances the metal’s corrosion resistance by removing impurities and creating a passive oxide layer. This technique is ideal for complex shapes and hard-to-reach areas, making it a popular choice in the medical and pharmaceutical industries, where cleanliness and precision are crucial.

Passivation

Passivation is a chemical treatment process that removes free iron from the surface of stainless steel, enhancing its corrosion resistance. Unlike polishing, passivation does not alter the metal’s appearance but significantly improves its durability. The process involves immersing the stainless steel in an acid solution, typically nitric or citric acid, which cleans the surface and encourages the formation of a passive oxide layer. Passivation is essential for applications where the material is exposed to harsh environments, such as marine and chemical processing industries, where maintaining the integrity of the metal is critical.

Chemical Polishing

Chemical polishing involves using a chemical solution to dissolve surface imperfections and achieve a smooth, reflective finish on the stainless steel. This technique is similar to electropolishing but does not require an electrical current. Chemical polishing can be a cost-effective alternative for achieving a high-quality finish, especially for large or irregularly shaped components. However, it’s essential to consider the type of stainless steel and the specific chemicals used, as some combinations may not be suitable. Chemical polishing is often employed in the aerospace and electronics industries, where precision and smoothness are essential.

Highest Standards of Quality

Choosing the right stainless steel polishing technique depends on various factors, including the desired finish, the complexity of the component, and the application requirements. By understanding the different types of stainless steel polishing techniques, you can choose the right method to ensure your stainless steel components meet the highest standards of quality and performance.

At CMPI, we specialize in stainless steel sheet polishing. With over 20 years of experience in the industry, we have the know-how to polish all kinds of stainless steel sheets and plates. We can polish your panels and cut them to size based on your exact specifications—get in touch with our team today to learn more.